Description

SensoPRO

Rapid Quality Control

It has never been so easy to perform rapid quality control in a production line. Thanks to SensoPRO, a production line operator only needs to load the sample and follow guided instructions to get a pass/fail report. Plug-in-based data analysis algorithms provide a high degree of flexibility. New modules can be easily customized to other industry needs.

MARKETS

Tailor-made solutions for every application

Our development team is used to working on customized solutions for those clients who do not find what they need among our other available packages. We offer the expertise of our engineers to find the solution that best suits the required application.

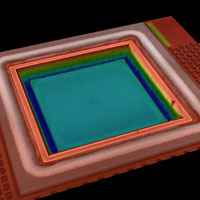

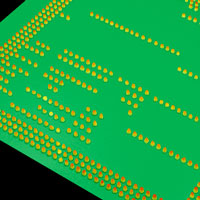

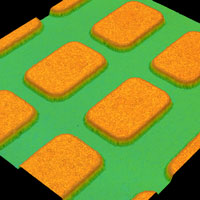

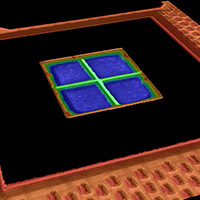

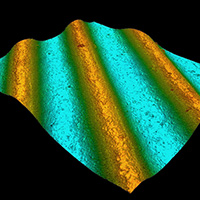

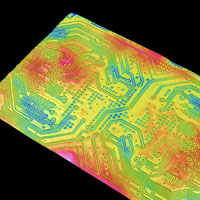

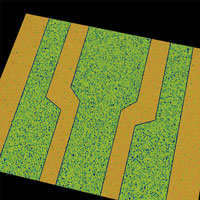

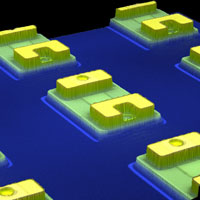

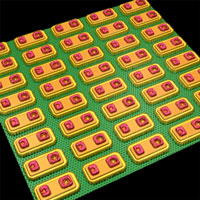

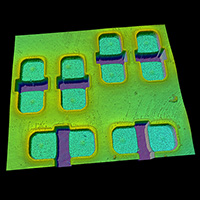

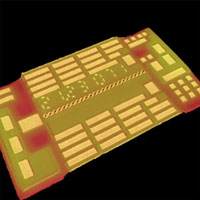

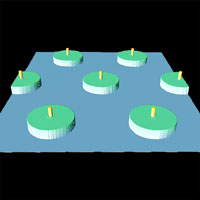

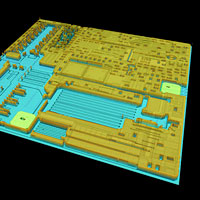

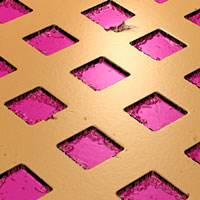

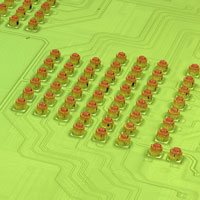

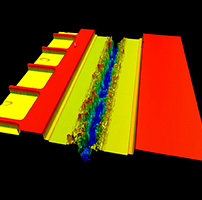

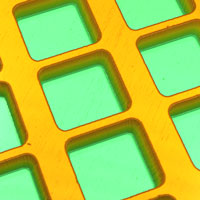

CONSUMER ELECTRONICS

The consumer electronics market includes Semiconductors, Printed Circuit Boards (PCBs) and Display industries, among others. SensoPRO has become a true money saving tool in many applications given its speed and automation.

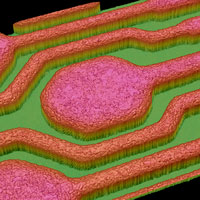

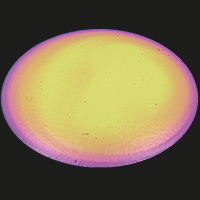

MEDICAL DEVICES

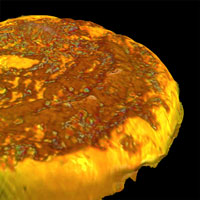

The medical market works with highly demanding quality control and quality assurance standards. Sensofar’s 3D optical profilers enable fast, non-invasive and accurate control of the manufacturing process, as well as the quality control of surface texture.

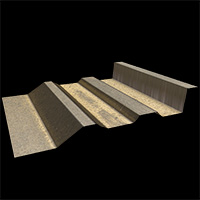

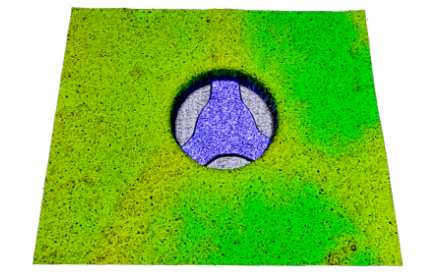

TOOLING

The designing and manufacturing of tools directly affects the production quality of the end-user industry. SensoPRO is extremely fast analyzing the dimensions measurements of the valleys, flanks and peaks of thread or calculating the cutting edge radius of inserts and other cutting tools.

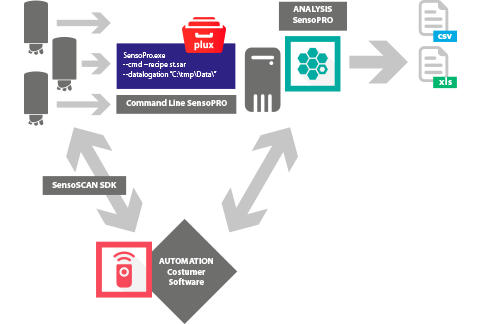

AUTOMATION

How does it work?

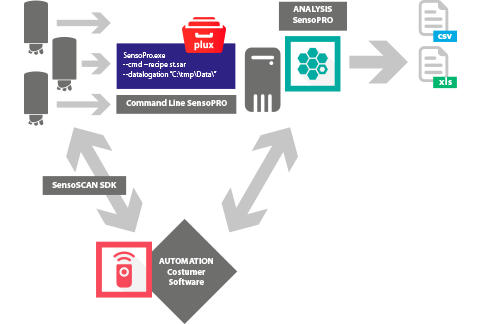

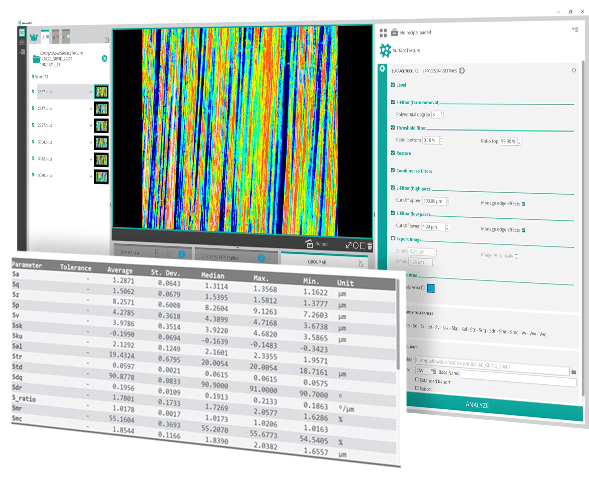

This 64-bit data analysis solution provides an environment for QA engineers and technicians to quickly and easily analyze production parameters. SensoPRO can be linked to the acquisition software (SensoSCAN) so that measured data can be automatically transferred to SensoPRO software and analyzed. Once configured, a single-click both acquires and analyzes the measurement data.

.png)

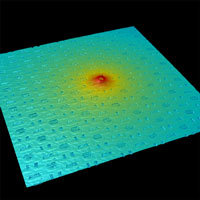

PERFORMANCE

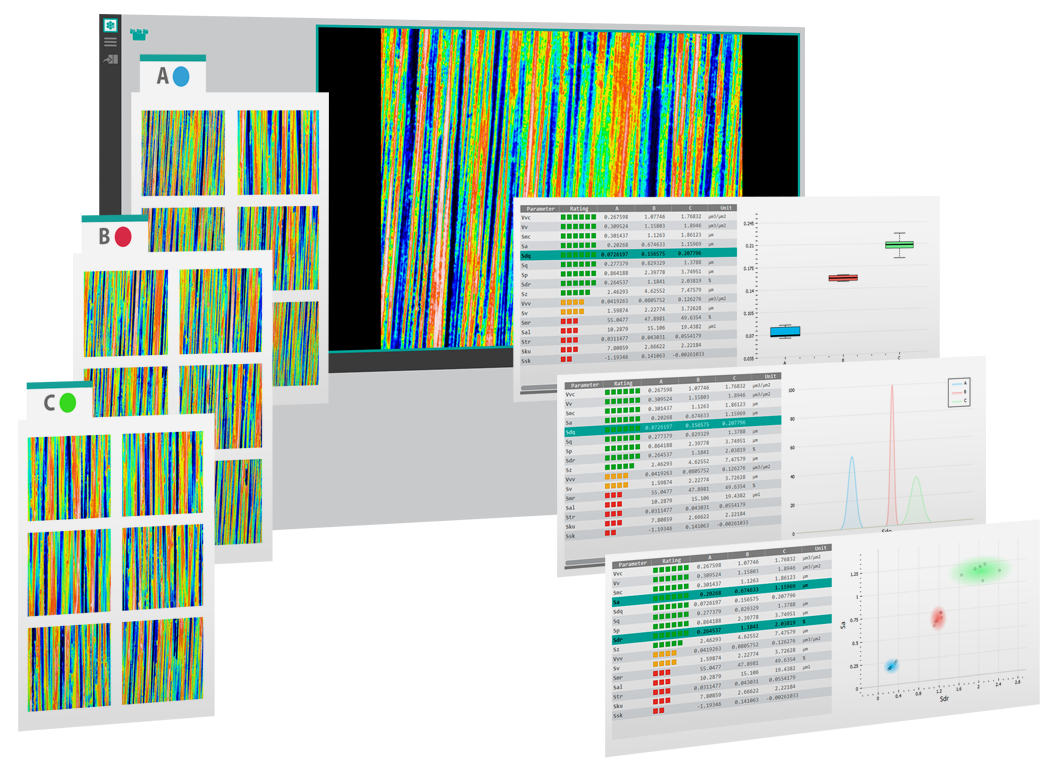

Guide tool for the QC manager

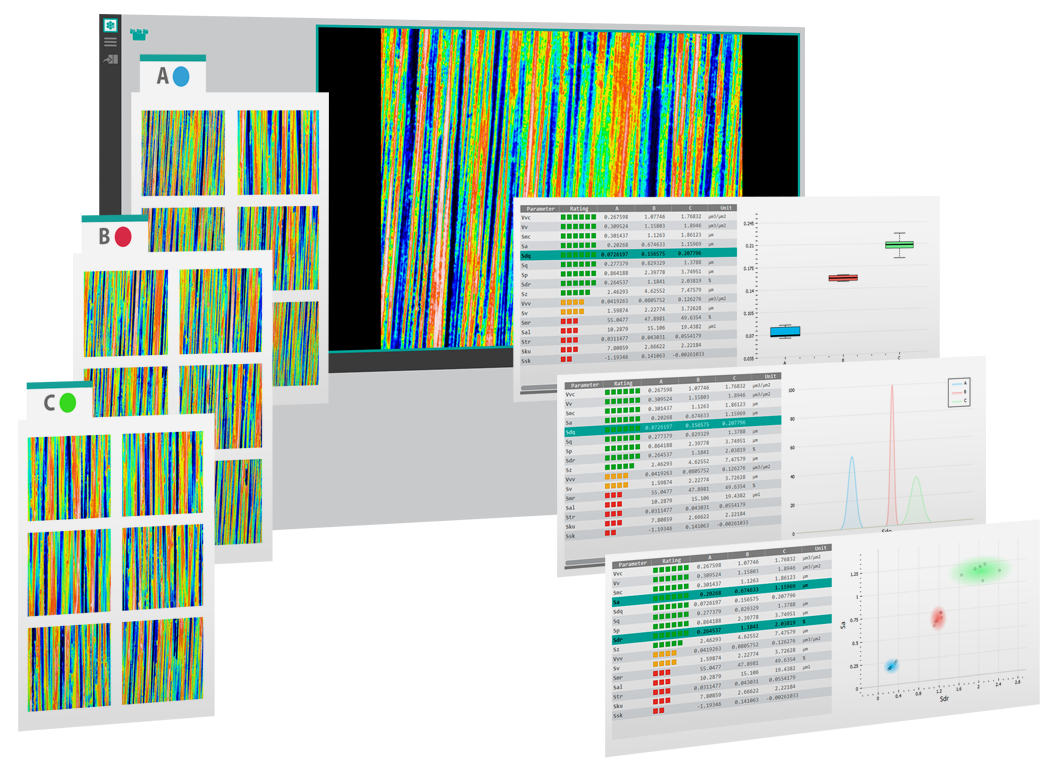

A revolutionary innovation for optical profilometers which substantially improves its usability and simplifies the task of setting tolerances when creating a recipe, as well as deciding which are the key parameters to control the production line by comparing multiple sets of data which also can be compared through a graphical representation. Specially conceived for non-expert users who need traceable production control.

PERFORMANCE

Extremely fast

As multiple cores can now be fully utilized, a larger number of actions can be implemented in parallel, thus resulting in higher overall system performance. Easy to handle larger files, and/or larger multiple data sets.

PERFORMANCE

Command line available

This tool is a solution to create proprietary applications able to manage SensoPRO to analyze measurement acquired with Sensofar systems. Combining this solution with SensoSCAN SDK, we can accelerate QC processes by analyzing in parallel (on a separate computer) while acquiring new measurements. Command line is an easy way to call SensoPRO analysis software from other software.

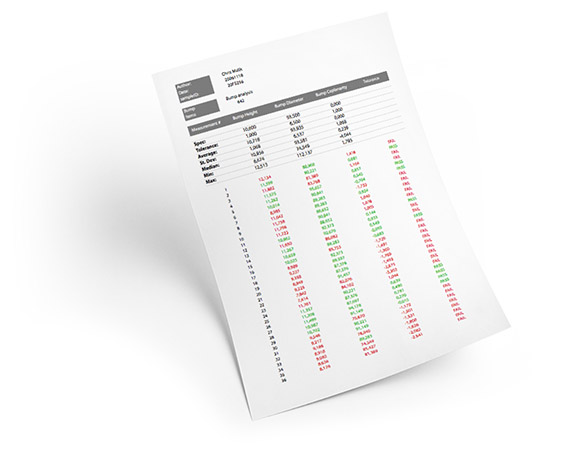

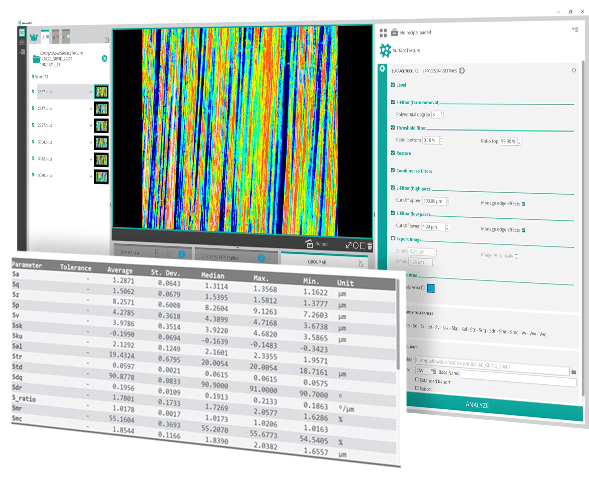

RESULTS

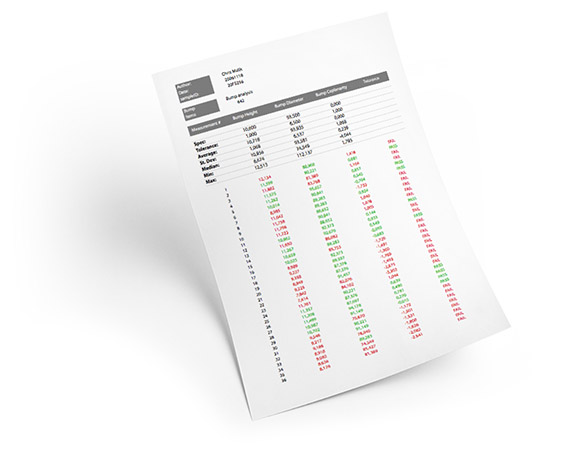

Parameter statistical analysis module

Once the analysis is done, the results and the standard deviations for each parameter are shown on a table. If any tolerances are applied, these will be highlighted in the summary section.

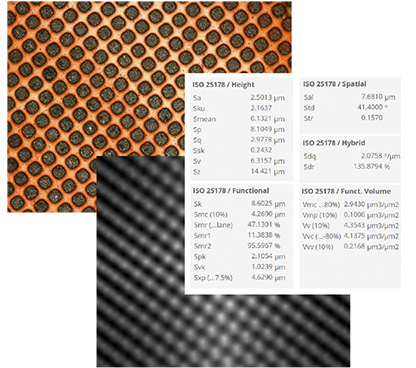

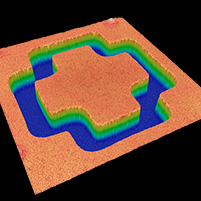

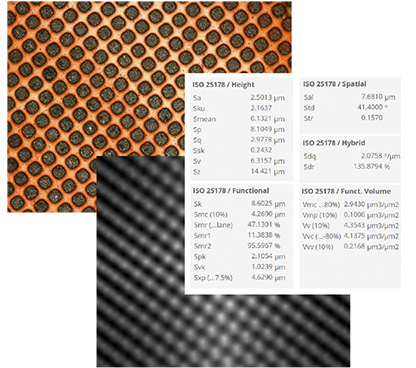

ISO STANDARD

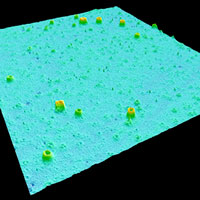

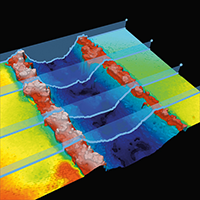

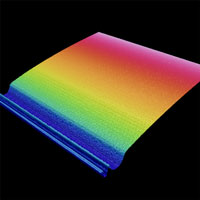

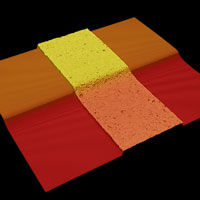

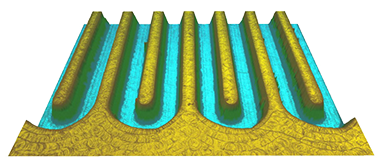

Surface texture characterization

The ISO 25178: Geometric Product Specifications (GPS) – Surface texture: areal standard is an International Organization for Standardization collection of international standards relating to the analysis of 3D areal surface texture. It is the first international standard taking into account the specification and measurement of 3D surface texture, and in particular defines 3D surface texture parameters and the associated specification operators.

Sensofar develops a Plugin to analyze surface texture (a.k.a. roughness) in accordance with the corresponding parameters defined by the ISO 25178.

Surface parameters are calculated according to ISO 25178:

- Height parameters (height values along the Z axis)

- Spatial parameters (spatial periodicity of the data)

- Hybrid parameters: (spatial shape of the data)

- Functional parameters (parameters calculated from the material ratio curve, surface into motifs, valleys and hills)

RESULTS

Exportable reports in multiple formats

Several options for managing the output files from a successful analysis are provided to get a complete report showing pass or fail results.

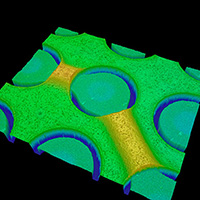

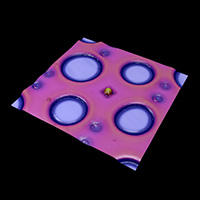

PLUGINS

Automatized custom analysis solutions

The SensoPRO data analysis application utilizes a module-based approach, where specific Plugin modules can be installed in the application.

SensoPRO Plugins

This Plugin-based data analysis approach also provides a high degree of flexibility and specificity, making use of targeted algorithms that are optimized to the exact application needs. New modules can be easily customized to other industry needs.

Each Plugin consists of:

A SET OF

Processing settings

Comprising threshold settings, filters, operators, crop settings, etc., that can be applied to the measured data before the analysis. Each SensoPRO Plugin has its own suite of processing settings.

A SET OF

Parameters & Tolerances

Set of fitting parameters and, selection of tolerances for further analyses. Optimizes the results, e.g. according to known results, scaling, (manufacturing) conditions and tolerances.

Default Plugins

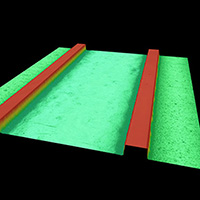

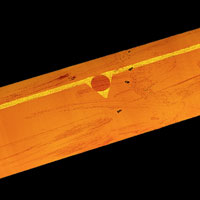

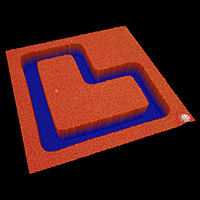

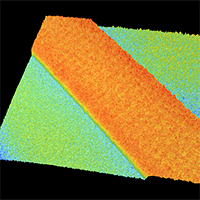

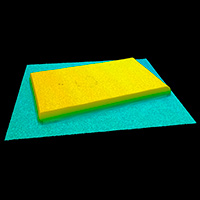

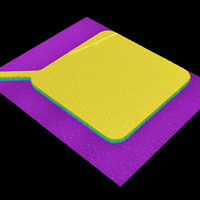

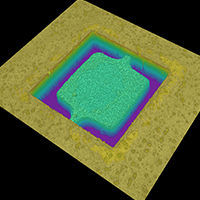

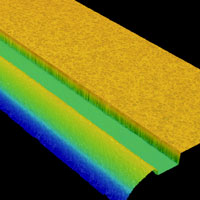

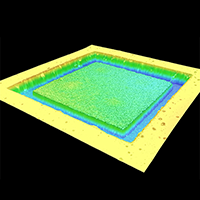

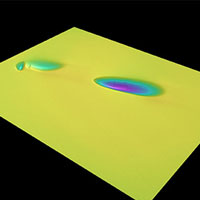

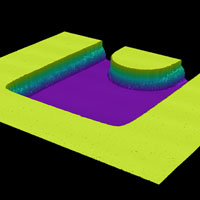

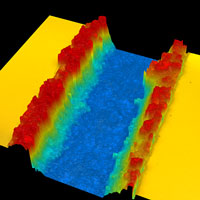

.jpg) STEP HEIGHT

STEP HEIGHT

.jpg) STEP HEIGHT ISO

STEP HEIGHT ISO

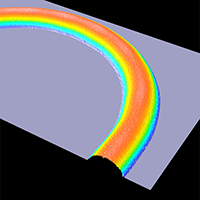

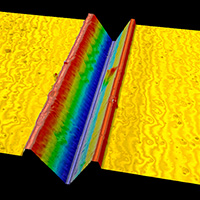

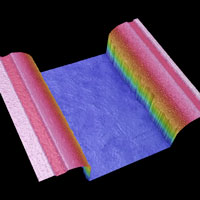

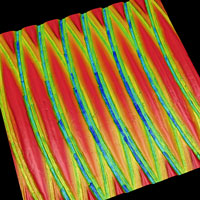

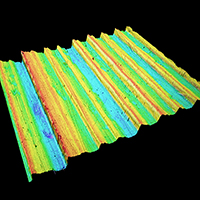

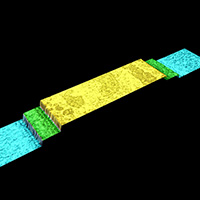

.jpg) SURFACE TEXTURE PROFILE

SURFACE TEXTURE PROFILE

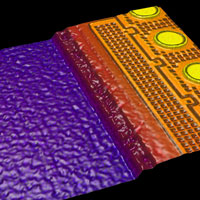

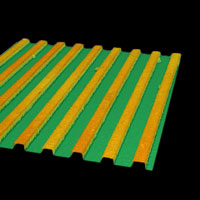

.jpg) SURFACE TEXTURE

SURFACE TEXTURE

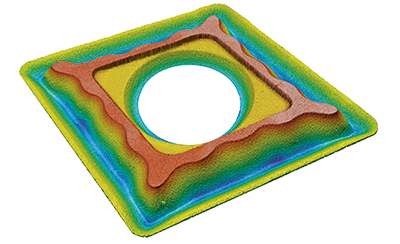

Optional Plugins

Watch our videos

This series of video tutorials has been made as a step-by-step guide to understanding each of our software’s functionalities. It is an easy way to share all of the new features achieved in each version release of SensoPRO and to accompany the users the first time they try them.

More detail about Radiant Advanced Devices Sdn Bhd

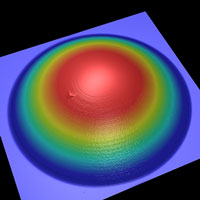

BARCODE

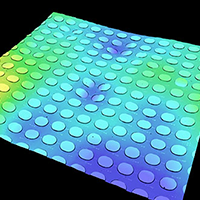

BARCODE BLOBS

BLOBS

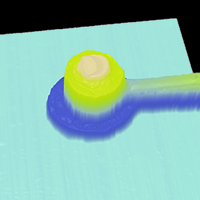

BUMP DISTANCE

BUMP DISTANCE C TRACE

C TRACE

CHIP ANGLE

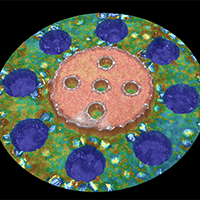

CHIP ANGLE CIRCLE CENTERS

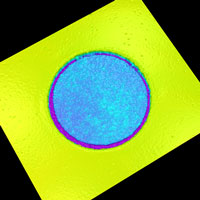

CIRCLE CENTERS CIRCLE PAD

CIRCLE PAD

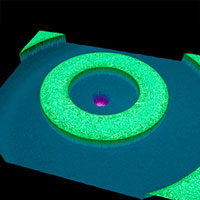

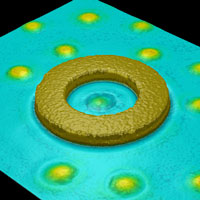

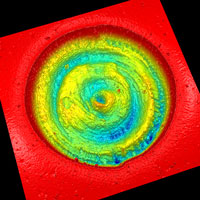

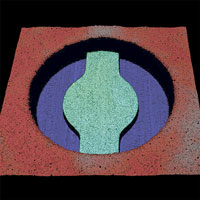

CONCENTRICITY

CONCENTRICITY CONCENTRICITY A

CONCENTRICITY A

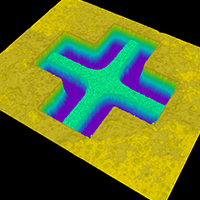

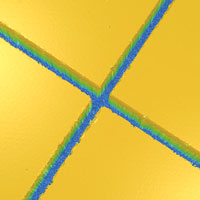

CROSS A PAD

CROSS A PAD CROSS B PAD

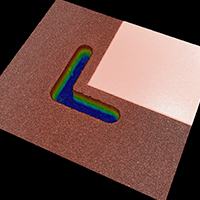

CROSS B PAD CROSS KERF

CROSS KERF CRUZ

CRUZ D DISTANCE

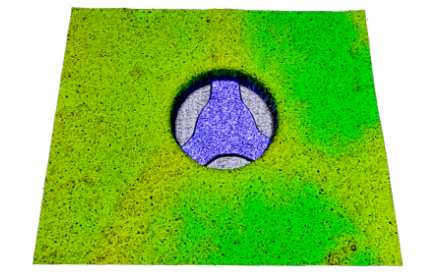

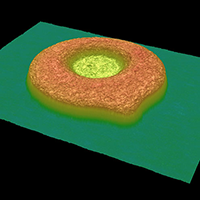

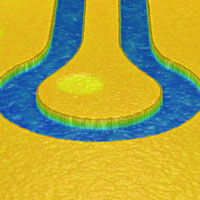

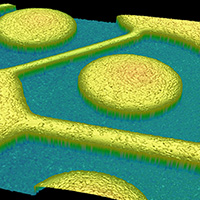

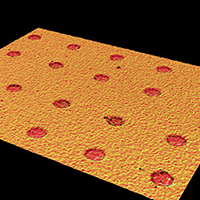

D DISTANCE DIMPLE

DIMPLE DIMPLE T

DIMPLE T DOUBLE CIRCLE

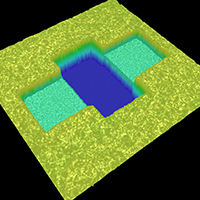

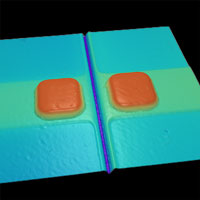

DOUBLE CIRCLE DOUBLE STEP HEIGHT

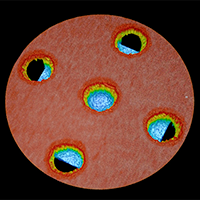

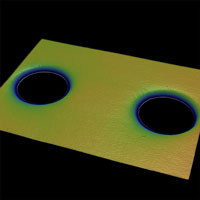

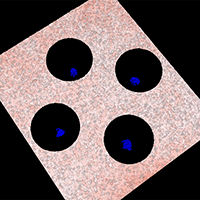

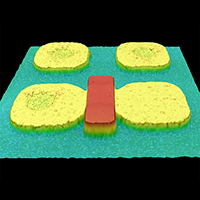

DOUBLE STEP HEIGHT DUAL HOLE

DUAL HOLE EDGE

EDGE F TRACE

F TRACE FLATNESS

FLATNESS FOUR STEP HEIGHT

FOUR STEP HEIGHT GLASS BUMP HEIGHT

GLASS BUMP HEIGHT GLUE

GLUE GLUE HEIGHT

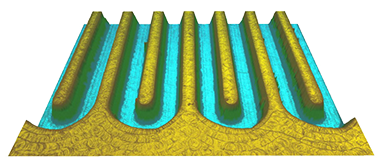

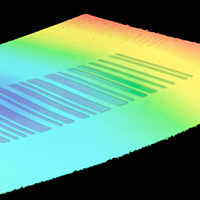

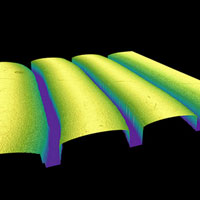

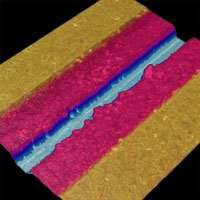

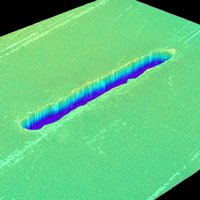

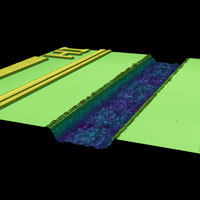

GLUE HEIGHT GROOVE PROFILE

GROOVE PROFILE GROOVE SPACING

GROOVE SPACING HALFCUT

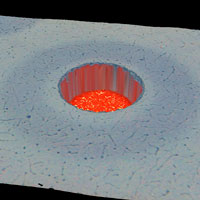

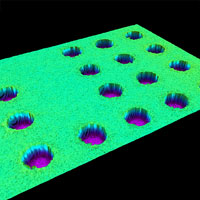

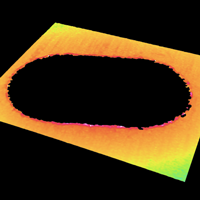

HALFCUT HOLE

HOLE IMAGE TRACE

IMAGE TRACE IMCC

IMCC L GROOVE

L GROOVE L PAD

L PAD LASER CUT

LASER CUT LASER DRILL

LASER DRILL LASER GROOVE

LASER GROOVE LASER HOLE

LASER HOLE LED ANGLE

LED ANGLE LED CHIP

LED CHIP MULTIPLE STEP HEIGHT

MULTIPLE STEP HEIGHT PAD

PAD PAD COPLANARITY

PAD COPLANARITY PAD DISTANCE

PAD DISTANCE PANEL PARTICLE HEIGHT

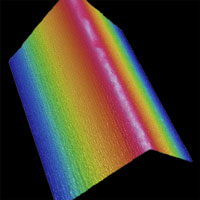

PANEL PARTICLE HEIGHT PANEL SLOPE

PANEL SLOPE PILLER

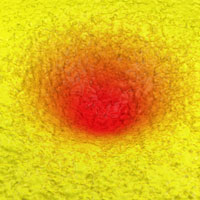

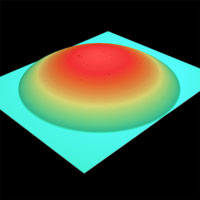

PILLER POWER

POWER PROBE MARK DEPTH

PROBE MARK DEPTH PROFILE TRACE

PROFILE TRACE PTV

PTV Q GROOVE

Q GROOVE R BUMP

R BUMP R HOLE

R HOLE R PAD

R PAD RESIST BRIDGE

RESIST BRIDGE SLOPE GROOVE

SLOPE GROOVE SLOT HOLE

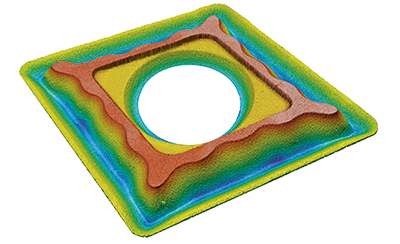

SLOT HOLE SOLDER MASK

SOLDER MASK SPACER

SPACER SPHERIC

SPHERIC SQUARE

SQUARE SQUARE GROOVE

SQUARE GROOVE SQUARE PAD

SQUARE PAD STEP HEIGHT

STEP HEIGHT STEP HEIGHT ISO

STEP HEIGHT ISO STEP NUMBER

STEP NUMBER SURFACE TEXTURE

SURFACE TEXTURE SURFACE TEXTURE PROFILE

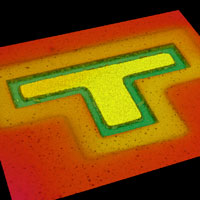

SURFACE TEXTURE PROFILE T PAD

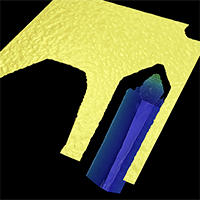

T PAD TAPER ANGLE

TAPER ANGLE THREE STEPS

THREE STEPS TRACE

TRACE TRACE CLIMB

TRACE CLIMB TRENCH

TRENCH TRIM

TRIM TRIPLE BUMP

TRIPLE BUMP V GROOVE

V GROOVE V HOLE

V HOLE VTP

VTP WAFER GLUE

WAFER GLUE WAFER GROOVE

WAFER GROOVE.jpg) WAFER GROOVE LINES

WAFER GROOVE LINES WAFER PAD

WAFER PAD X PAD

X PAD

.png)

.jpg) STEP HEIGHT

STEP HEIGHT.jpg) STEP HEIGHT ISO

STEP HEIGHT ISO.jpg) SURFACE TEXTURE PROFILE

SURFACE TEXTURE PROFILE.jpg) SURFACE TEXTURE

SURFACE TEXTURE