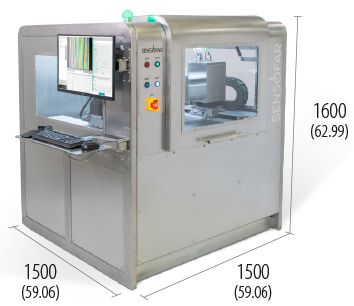

The S neox Grand Format offers a complete solution, from the hardware to the software perspective, for 3D surface measurements of large panels in semiconductor, display, and PCB industries.

Expansive 600 x 600 mm travel range with an impressive speed of one meter per second. Close-loop XY gantry design for consistent performance regardless of sample weight.

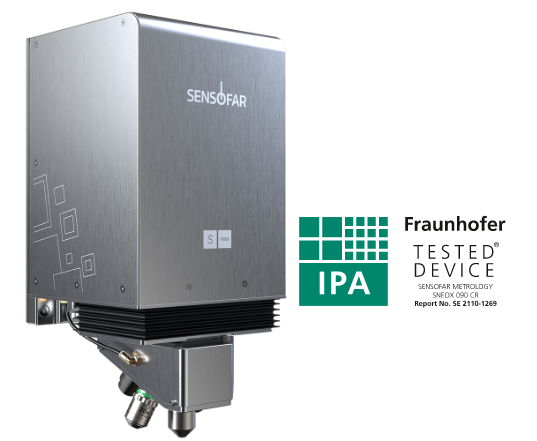

This system has been carefully designed to meet several industry standards, like the SEMI S2 and S8, and has also been certified by TÜV Rheinland.

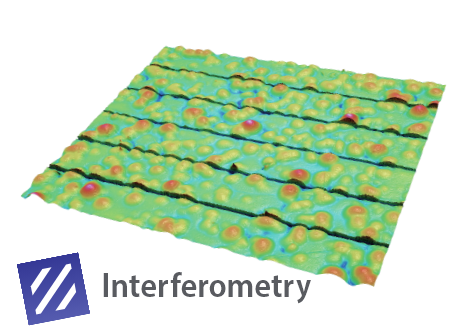

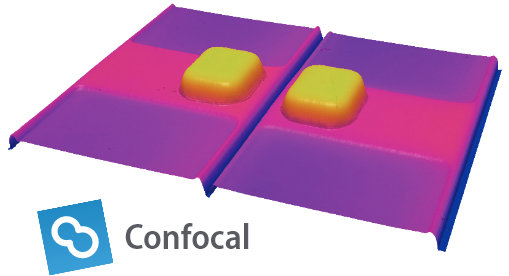

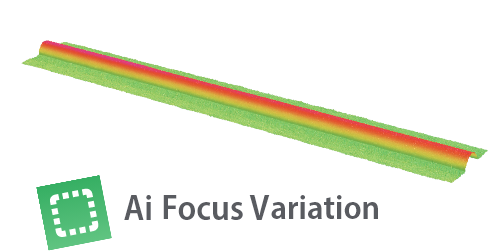

3-in-1 TECHNOLOGIES

Highest measurement versatility

The measuring sensor, the S neox Cleanroom, provides three different optical technologies to image with the most suitable technology for each specific sample, achieving precision down to subnanometer levels.

The measuring sensor is Class 1 compatible. The enclosure is made of stainless steel, minimizing particle emissions.

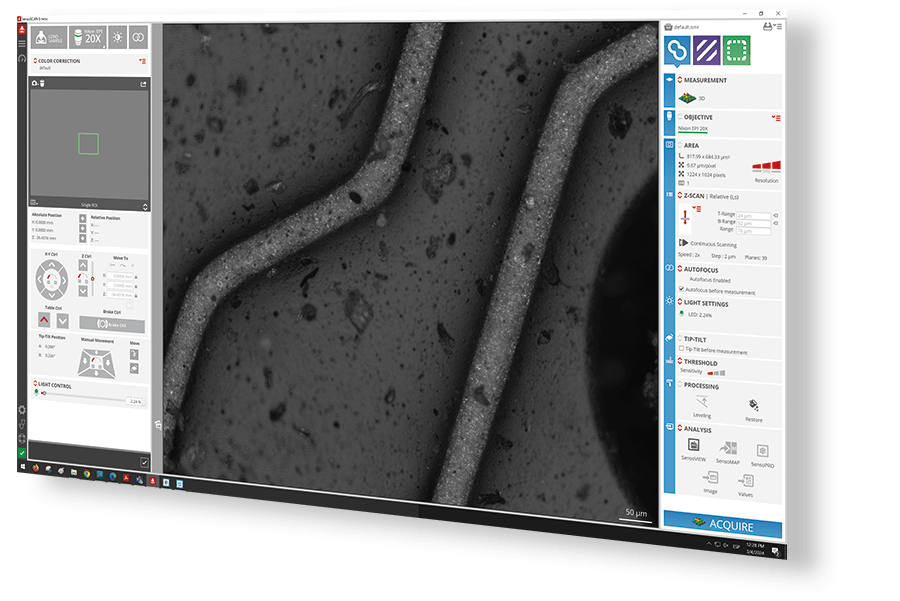

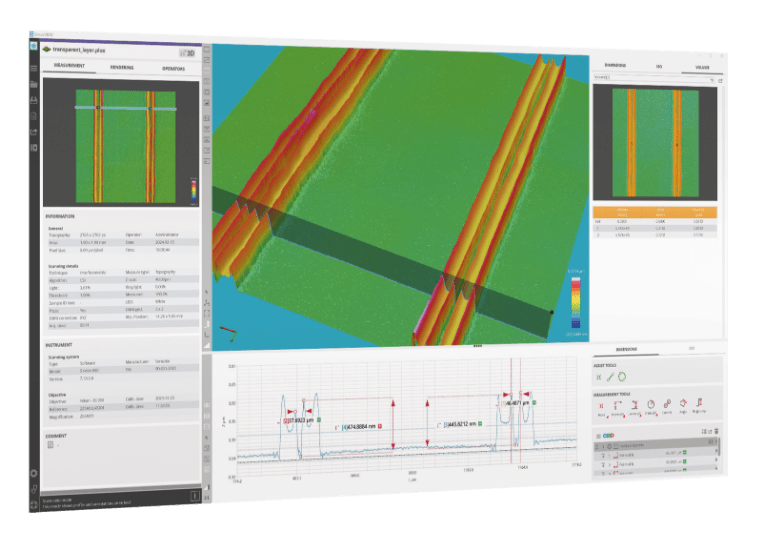

This advanced metrology tool is fully controlled by the easy-to-use SensoSCAN, which offers enhanced features for measurement automation.

Rapid Quality Control

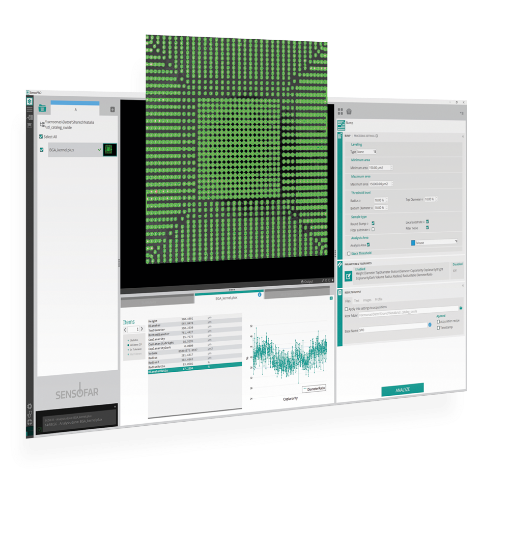

SensoPRO has an extensive suite of plugins, addressing common automation analysis needs and custom applications.

SensoPRO software provides analysis automation in QC and QA, efficiently handling large volumes of data. We have provided a range of custom plugins to meet specific requirements in the consumer electronics sector.

Powerful Analysis Software

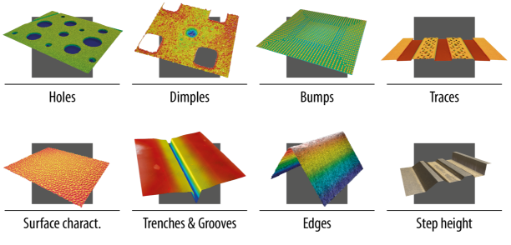

SensoVIEW is the ideal analysis software for a wide range of tasks. It features a complete toolkit for preparing and extracting data from both 2D and 3D datasets.

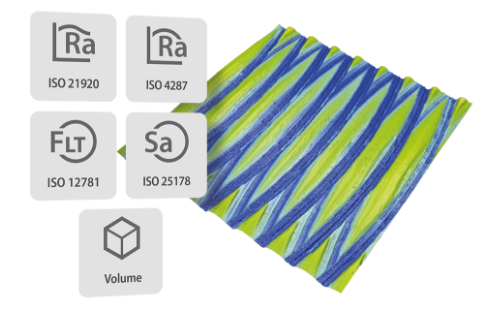

SensoVIEW provides dedicated operators with a user-friendly, step-by-step interface for extracting flatness and surface texture parameters, following the corresponding ISO standards, volume calculations, and more.

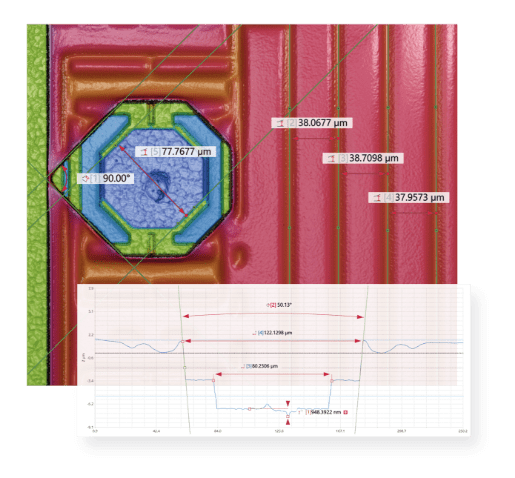

A variety of tools for critical dimensions are available for contour and profile views. Each one is equipped with an auto-adjustment feature and the capability to incorporate tolerances, ensuring a thorough dimensional analysis.

Profiler technologies

Light sources

Dimensions. mm (inch)

Objective lenses

| MAG | 5X | 10X | 20X | 50X | 100X | 150X |

| NA | 0.15 | 0.30 | 0.45 | 0.80 | 0.90 | 0.90 |

| WD (mm) | 23.5 | 17.5 | 4.5 | 1.0 | 1.0 | 1.5 |

| FOV1 (µm) | 3378 x 2826 | 1689 x 1413 | 845 x 707 | 338 x 283 | 169 x 141 | 113 x 94 |

| Spatial sampling2 (µm) | 1.38 | 0.69 | 0.34 | 0.13 | 0.07 | 0.05 |

| Optical resolution3 (µm) | 0.94 | 0.47 | 0.31 | 0.18 | 0.16 | 0.16 |

Confocal / Ai Focus Variation

| System noise4 (nm) | 100 | 30 | 8 | 4 | 3 | 2 |

| Maximum slope5 (º) | 9 | 17 | 27 | 53 | 64 | 64 |

1 Maximum field of view with 3/2” camera and 0.5X optics. 2 Pixel size on the surface. 3 L&S: Line and Space. Values for blue LED. 4 System noise measured as the difference between two consecutive measures on a calibration mirror placed perpendicular to the optical axis. 5 On smooth surfaces, up to 71º. On scattering surfaces, up to 86º.

| MAG | 2.5X | 5X | 10X | 20X | 50X | 100X |

| NA | 0.075 | 0.13 | 0.30 | 0.40 | 0.55 | 0.70 |

| WD (mm) | 10.3 | 9.3 | 7.4 | 4.7 | 3.4 | 2.0 |

| FOV1 (µm) | 6756 x 5652 | 3378 x 2826 | 1689 x 1413 | 845 x 707 | 338 x 283 | 169 x 141 |

| Spatial sampling2 (µm) | 2.76 | 1.38 | 0.69 | 0.34 | 0.13 | 0.07 |

| Optical resolution3 (µm) | 1.87 | 1.08 | 0.47 | 0.35 | 0.26 | 0.20 |

| System noise4 (nm) | PSI / ePSI 0.1 nm (0.01 nm with PZT) CSI 1 nm | |||||

| Maximum slope5 (º) | 4 | 7 | 17 | 24 | 33 | 44 |

1 Maximum field of view with 3/2” camera and 0.5X optics. 2 Pixel size on the surface. 3 L&S: Line and Space. Values for blue LED. 4 System noise measured as the difference between two consecutive measures on a calibration mirror placed perpendicular to the optical axis. For PSI, 10 phase averages with vibration isolation activated. The 0.01 nm are achieved with Piezo stage scanner and temperature controlled room. Values for green LED (white LED for CSI). Resolution HD. 5 On smooth surfaces, up to 71º. On scattering surfaces, up to 86º.

Gantry XY stage

| Positioning system | Two axes Gantry: XY translation of the head |

| Travel range (mm) | 600 x 600 |

| Travel speed | Max. 1m/s |

| Control type | Linear close loop |

This system has been carefully designed to meet several industry standards, like the SEMI S2 and S8, and has also been certified by TÜV Rheinland.

The S neox Cleanroom sensorhead has been carefully engineered to be compatible with ISO Class 1 and ESD compatible.