Flow Rack / Dynamic Storage Racking System consist of a number of systems that to be added into pallet racking system to work with pallets,tote boxes or cartons. It is suitable for goods that perish quickly, e.g. foodstuffs. Via Flow Rack / Dynamic Storage Racking System, it would ensure these product being stored & retrieve fast enough to ensure the stock rotation could match perfectly with the expiry dates.

3 types of Flow Rack / Dynamic Storage Racking System comes in three different forms:

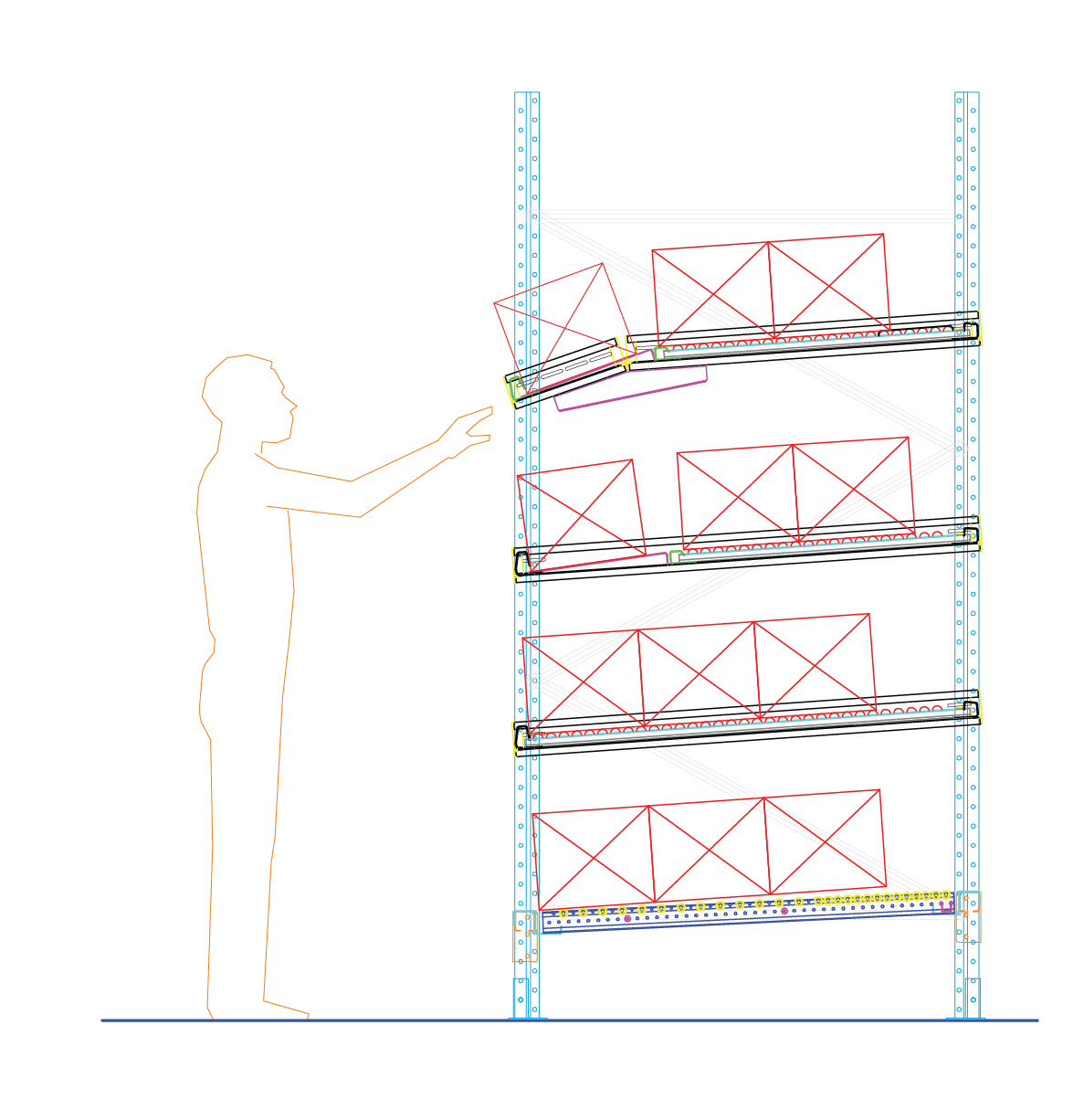

1. CARTON FLOW

This is a design which works by inserting goods into the back of the structure and removing them from the front.

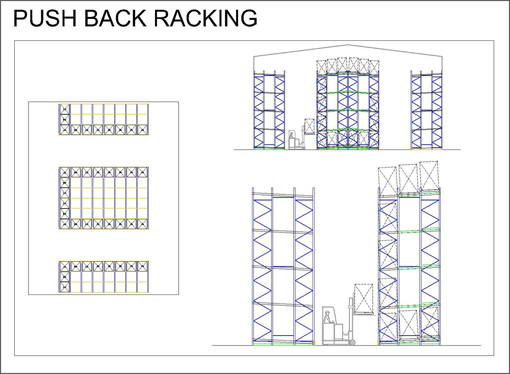

2. PUSH BACK RACKING

This method uses special beams and pushback assembly subframes running front to back in each bay. The tracks are mounted at an angle so when a forklift truck pushes a pallet into a bay, the one that is already there is pushed backwards. When the pallet at the front is removed, the one behind it will roll to the front.

One of the features of this system is that the pallets can be stocked four deep, conserving space and allowing easy organizing of your stock

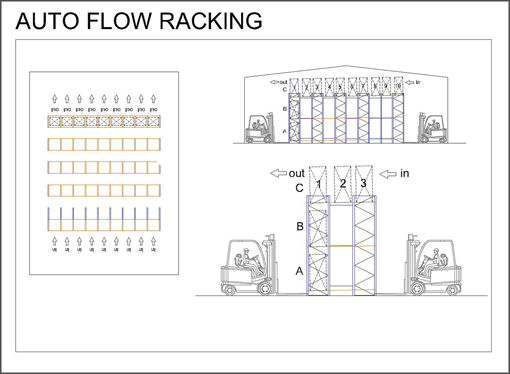

3. AUTO FLOW RACKING

This works in exactly the same way as carton live storage except on a much bigger scale. Whole pallets can be stored in this way making it ideal for fast moving, perishable goods that are received and dispatched in large quantities.

One of the main features of using this system is that any size and shape of pallet can be handled.