An Innovation-Driven Approach by Obsnap Instruments Penang

As digital manufacturing continues to evolve, the intersection of 3D scanning and 3D printing has become a critical component of modern product development. While 3D printing enables the rapid fabrication of complex parts, its effectiveness is significantly amplified when paired with high-precision 3D scanning systems. At Obsnap Instruments Penang, we empower Malaysian industries to unlock this synergy—offering industrial 3D scanning solutions that streamline design, optimize production, and elevate final part quality.

🔧 Understanding the Integration : 3D Scanning + 3D Printing

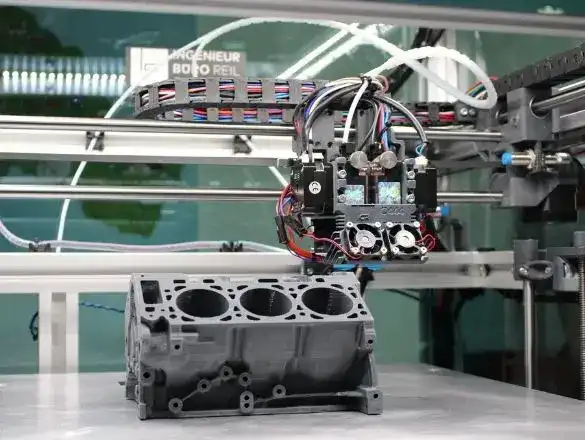

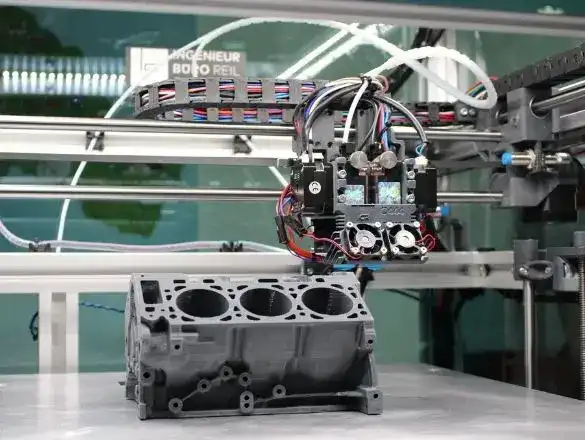

3D printing, or additive manufacturing, constructs parts layer by layer using digital design data. However, without accurate and validated input, the output may suffer from dimensional errors or functional mismatches. That’s where 3D scanning enters the picture. 3D scanning uses laser technologies to digitize the surface geometry of physical objects with high resolution and accuracy. When integrated into the 3D printing workflow, scanning ensures that the digital model is a true representation of the physical object allowing for reverse engineering, modification, replication, and post-print validation.

🧩Key Applications of 3D Scanning in 3D Printing Workflows

✅ Reverse Engineering for Print-Ready Models

One of the most valuable applications is the ability to recreate discontinued or custom parts by scanning the existing physical object. This is essential in industries like automotive, aerospace, and heavy equipment, where replacement parts may lack CAD files.

✅ Design Iteration & Digital Prototyping

After an initial 3D print, scanning the part helps identify design flaws or warping, which can then be corrected in CAD software. This speeds up the iteration cycle and ensures more accurate final outputs.

✅ Print-to-CAD Comparison

Post-print inspection compares the printed object against the original CAD model to detect dimensional deviations, warping, shrinkage, or print artifacts. This is particularly important in high-precision sectors like aerospace and medical manufacturing.

✅ Legacy Part Digitization

Old parts with no digital documentation can be scanned to create parametric CAD files. These files can then be enhanced, adjusted, or directly reprinted extending product lifecycle support for obsolete components.

✅ Customization & Personalization

For applications such as orthotics, dental models, or custom-fit wearables, scanning the user’s body part ensures that 3D-printed components offer a perfect ergonomic or anatomical fit.

📊 Benefits for Engineering & Production Teams

By integrating 3D scanning into additive manufacturing, engineering teams gain:

- Improved Design Accuracy: Ensure printed parts match real-world constraints

- Faster Time-to-Market: Eliminate trial-and-error design phases

- Cost Reduction: Avoid production errors and reprints by validating before fabrication

- Enhanced Quality Control: Automate inspections and achieve traceability

- Digital Workflow Integration: Seamlessly transfer between scan data, CAD, and printing

🏭 Industries Leading the Adoption in Malaysia

At Obsnap Instruments Penang, we support customers across a wide spectrum of industries that increasingly rely on this digital workflow:

- Automotive – custom parts, tooling, and jigs

- Aerospace – lightweight structures and performance-driven geometries

- Medical Devices – patient-specific devices and surgical planning models

- Consumer Goods – ergonomic design verification and aesthetic validation

- Tool & Die – rework, repair, and reproduction

- Heavy Industry – large-scale part reproduction and maintenance support

🌐 Supporting Digital Manufacturing

As manufacturers shift toward smart and digital production lines, Obsnap Instruments Penang delivers value through:

- 🔍 Expert Consultation – In-depth analysis of part geometry, resolution needs, and scan environments

- 🧰 Custom Workflow Integration – Aligning 3D scanning with your CAD and printing tools

- 🧑🏫 Training & Support – On-site setup, user training, and technical troubleshooting

- 🔄 Measurement-as-a-Service – Outsourced scanning and inspection for specialized projects

- 📈 Scalability – Scanning systems for prototyping, batch production, or full automation

📞Ready to Improve Your Addictive Manufacturing with Digital Precision

Whether you're looking to reverse engineer complex parts, inspect 3D printed components, or improve your design workflow—Obsnap Instruments Penang offers reliable solutions tailored to your specific industry needs.

Japan

Japan